I’ve been a bit quiet about the the Good Night Lamp but this year was major. I actually made and shipped lamps around the world. Here is a rather long breakdown of how I did it, how much it cost and what’s next.

A bit of history I had the idea in 2005 as a student in Italy. I made some rather basic plastic lamp-shaped prototypes with a technician at the Interaction Design Institute Ivrea and presented it to Droog who had set us a design brief around single household living in the future. They took it under consideration for about 6 months, but after presenting to their team in Amsterdam (I was living there at the time) they said it didn’t fit their aesthetics. I think it just was too complicated for their whimsical collection. I also had no idea how to manufacture it at all. I had a prototype based on a hacked remote control toy car.

I moved to London in 2007, ran a design studio and the first UK distributor of the Arduino with Massimo Banzi. We talked about it with Matt Biddulph a lot but not much was done. I still had the now empty plastic prototypes on my desk at the office. We closed Tinker on December 3rd 2010.

In March 2012 after I dusted myself off from closing Tinker, I registered Good Night Lamp Ltd at Companies House, trademarked the name in the UK and booked the second smallest booth you could get at CES 2013. At that time I roped in Adrian McEwen as CTO, John Nussey as Head of Products and Konstantinos Chalaris as Design Lead. We had a two day workshop in the summer of 2012 with Lawrence Archard, an electronics engineer. We came up with the idea of a house as a shape and chose to connect the lamps using wifi based on a very high level cost breakdown.

Kostas designed the first shape and our distinctive roof angle and we wanted each Little Lamp to connect and share power with the others that might be near it. This would let people build a bit of a village.

That summer I also asked around me for financial support and Usman and Blaine came to the rescue with a combined £20K. I used that money to pay for the prototypes to be made by Tom Cecil Studio for CES and get us there (that trip alone cost £14K). I started meeting investors in autumn 2012 and was offered in my first meeting £40K if I could find others to join in. They never materialised so I decided to run a Kickstarter campaign while at CES. We worked with PAN to come up with a video and photography for the campaign. We made a xbee-based prototype and with John, went to Vegas.

I never realised the press picked up their releases and did their coverage on the Monday while we were still setting up so we missed the boat a tad but the event was a real eye opener. We had a lot of interest in the product but being one of two Kickstarter projects there people really wanted to see a final product. We had some good coverage, but the inability to deliver right there and then really affected people’s perception. ‘That’s interesting’ is something you get a lot when people can’t buy it right there and then. We failed our campaign and investor interest basically disappeared as a result. I stopped working with the guys as I couldn’t pay them anymore. I went back to square one and continued meeting investors for about 6-8 months and applying for funding and incubators. It was summer 2013 when I understood I was going to have to go it alone with no further financial support than what I could get from the consultancy work I do and the speaking engagements I have. I got an agent (thanks Ben) and started working with some great clients and just kept going.

I also continued showcasing the Good Night Lamp in the UK at various tradeshows. The most important one for me was the Gadget Show Live in Birmingham.

Visited mostly by working class dads and their sons, their reaction to wifi was quite telling. ‘Oh nan doesn’t have wifi’. So I pretended a 3G version was coming up and got a lot more sign ups for our newsletter. This was the turning point in terms of technological direction towards a GSM version.

In early 2013 I was working with the Eyehub project helping with dissemination, something I’d done with Lirec. I met Eseye at that point, an M2M company based in Guildford. The perfect match for the change I’d decided to make.

I worked with Daniel for about 6 months in early 2014 and he helped with web design and the strategy for production. I went live with a humble little shop and a paypal link (soon replaced by Stripe) in September 2014. 200 lamps were pre-ordered by over 60 customers around the world in a few weeks. I closed the shop link and got to work. The first lamps were shipped to customers in April 2015 and more have sold and shipped for Christmas. I’m now preparing to make about 2K-3K to sell to the UK, Europe and the US and ride the 2016 Christmas wave properly next year. It’s taken some time to get all the ducks in a row and it’s still work in progress.

Now what

I now have a CE certified product made in batches in the UK. The enclosure is made by Tom Cecil in London, the electronics and data supplied by Eseye in Guildford and the assembly and shipping will be handled by EPS in Woking. I’ve also been working with Burgopak on some packaging for each lamp before it goes into a box. I’m also working on a proper back end to help manage the lamps remotely with Andrew & Boris. A British product through and through (except for where the electronic components come from sadly) for the UK & EU markets. I’m working on getting a version of the product made in the US (Tennessee & Alabama) for the US market but that’s still in its infancy. It’s been tiring, stressful and expensive overall and I don’t think I’d do it in the same way if I had to start from scratch. But it’s also the best thing I’ve ever done.

I now have a CE certified product made in batches in the UK. The enclosure is made by Tom Cecil in London, the electronics and data supplied by Eseye in Guildford and the assembly and shipping will be handled by EPS in Woking. I’ve also been working with Burgopak on some packaging for each lamp before it goes into a box. I’m also working on a proper back end to help manage the lamps remotely with Andrew & Boris. A British product through and through (except for where the electronic components come from sadly) for the UK & EU markets. I’m working on getting a version of the product made in the US (Tennessee & Alabama) for the US market but that’s still in its infancy. It’s been tiring, stressful and expensive overall and I don’t think I’d do it in the same way if I had to start from scratch. But it’s also the best thing I’ve ever done.

Here are some very technical pieces of advice for anyone wanting to get into the business of making a consumer connected product.

Making is waiting

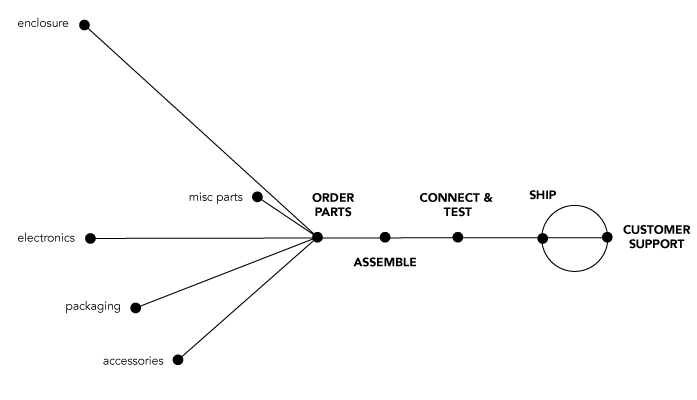

There are only 3-4 categories of things you will be ordering (eclosures, electronics, packaging, mis parts, accessories, packaging) but each one of them has a high chance of being delivered late which means you can’t start to really assemble things for *weeks* sometimes. It’s super frustrating, but save yourself and just assume it’s always going to happen and have plenty of plan Bs. You’re not Apple, chances are you never will be, so you can’t squeeze your vendors aggressively. Just plan for at least 1 to two months of delays on everything you order.

Keep things very, very local

Even within the London-area which is where the lamps are made, the fact that the enclosures are made in E10 and the rest happening around Guildford means I’m spending a fortune on couriers moving things from one end of London to the other. Customer returns are being returned to me in Brixton so far thanks to a pretty neat Freepost return labels, but then I need to get them couriered to Woking again. Very expensive. So keep every process very close. No working from your bedroom won’t do if you’re making hundreds of something. So have a plan.

Have a really good plan for customer support

Eseye are my first line of support for customer enquiries, this is normal because I don’t have great API access or a back end to connect to, but it makes the process of assessing what’s wrong with a customer really painful. It’s not their fault, the Good Night Lamp is a unique product in the M2M space. Usually, you’re only taking a sensor reading locally and sending some data back, end of story. And the product isn’t a consumer one, so the user-generated problems don’t really exist. The Good Night Lamp is an ‘if this then that’ structure with units all over the world in real people’s hands. Super tricky to both assess what is going on and where the problem is for a customer. I’m using Zendesk but really don’t like it. Not sure what else to use, so still working that out. Anyway, have a plan.

Expect you’ll lose a lot of money at first

I’ve lost over £70 / lamp so far in unexpected courier costs, returns, delays, pricing, etc. That’s ok as I have other clients too so it helps, but it’s not a long-term strategy. I don’t want someone else’s money to help with that either, I’d rather build a solid business with vendors who all know how to work with each other and work to cover my costs. More importantly, I see it as an investment in my continued eduction as a business owner and designer. This goes against the rhetoric of raising lots of money first and spending it (usually badly) after but I think there’s less pressure this way and the right design decisions are made. This all takes a lot of time, but the rewards happen daily: a nice email from a customer, a good prototype, more ideas for packaging. All part of the job.

Keep talking

I’ll spend more and more of my time in 2016 on marketing the Good Night Lamp and see if it has international appeal. You have to be careful about burning yourself out on these types of things. Because this is my third business, I think I’m more prepared. You can never stop talking about the product and I’ll do that more and more. It may bore the living daylight out of your friends and family, but having a product is like running a marathon. You are rewarded for sticking around and being pig-headed, not tiring yourself too quickly.

I’d never describe the last ten years is as an incredible journey, if anything it’s like hiking up a narrow badly-lit road on the side of a mountain during a blizzard. But I’m there because I want to be there and that’s the difference. Happy New Year everyone.

1 comment

Comments are closed.